Scrap balers

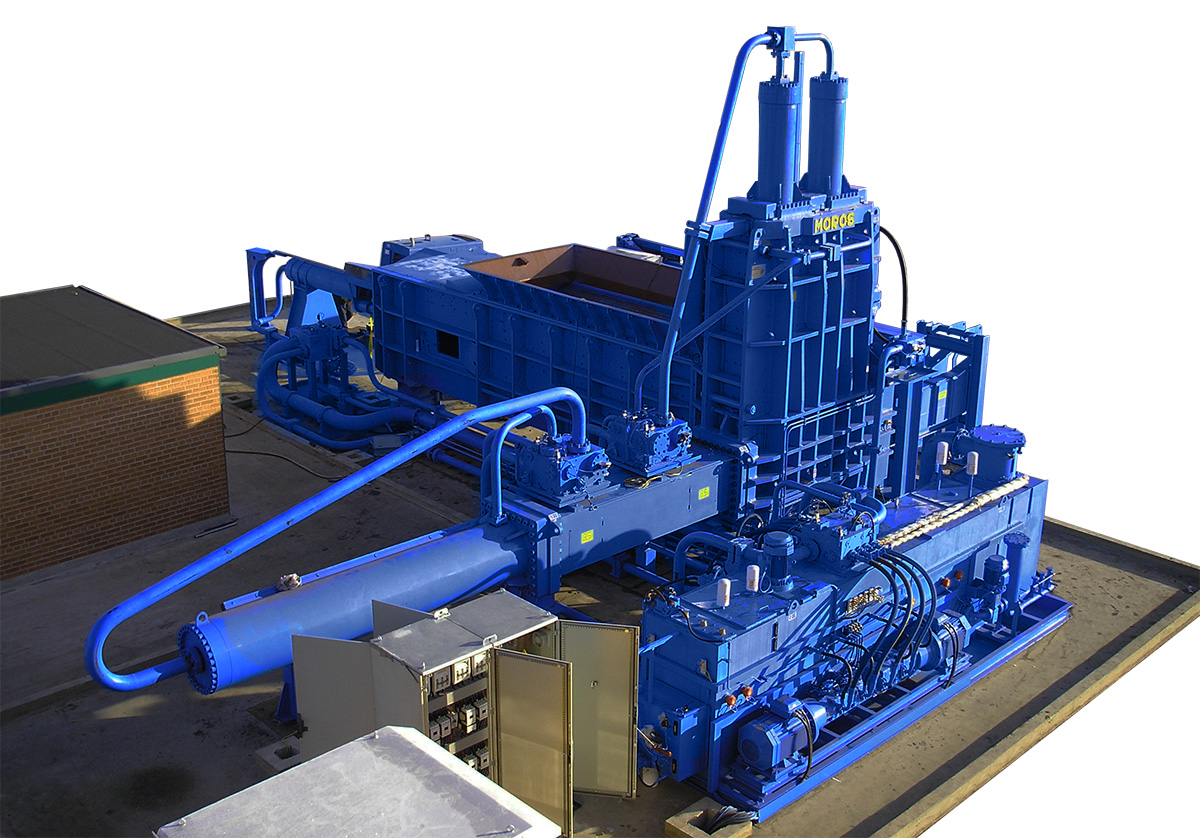

HIGH DENSITY BALERS

GC-S-800

The GC-S- 800 baler was designed to reach bale densities and productions that no other machine can achieve.

Its technical advantages mean that jamming is impossible in this machine, which can bale any material and format.

This machine is unique and has no competition on the international market.

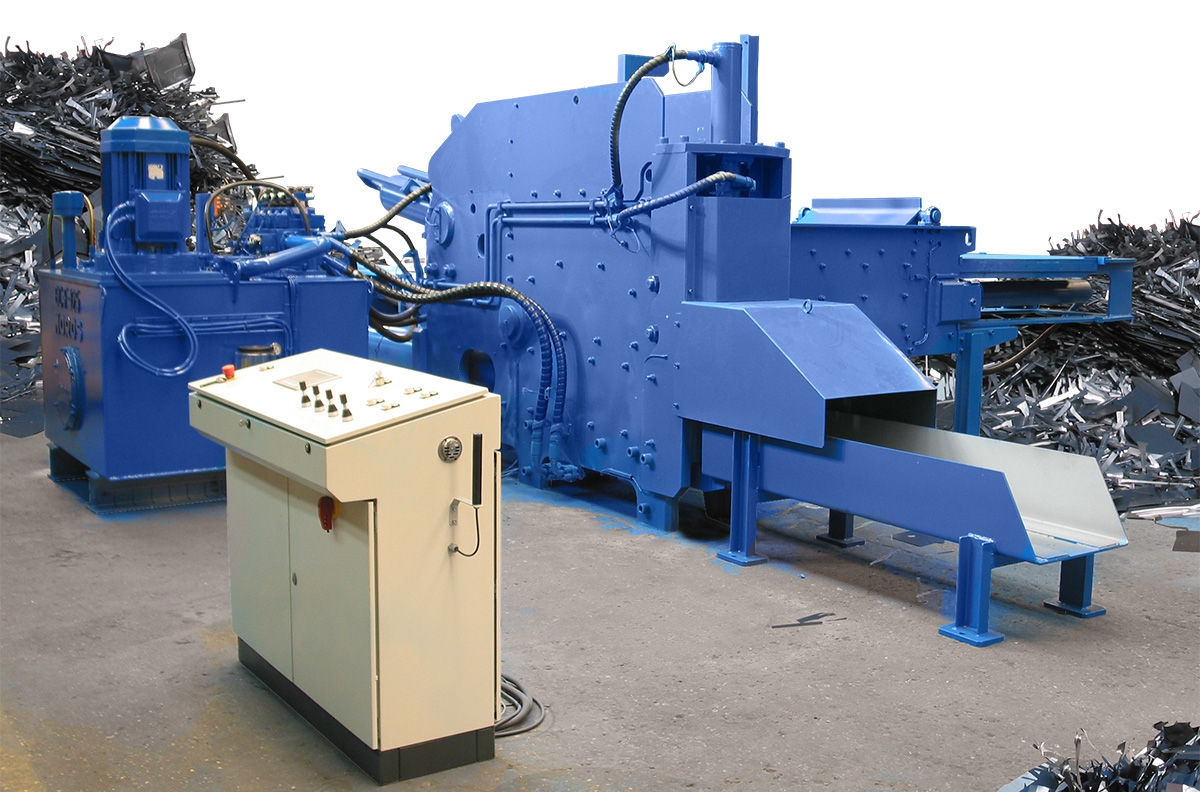

ONE, TWO AND THREE COMPRESSION BALERS

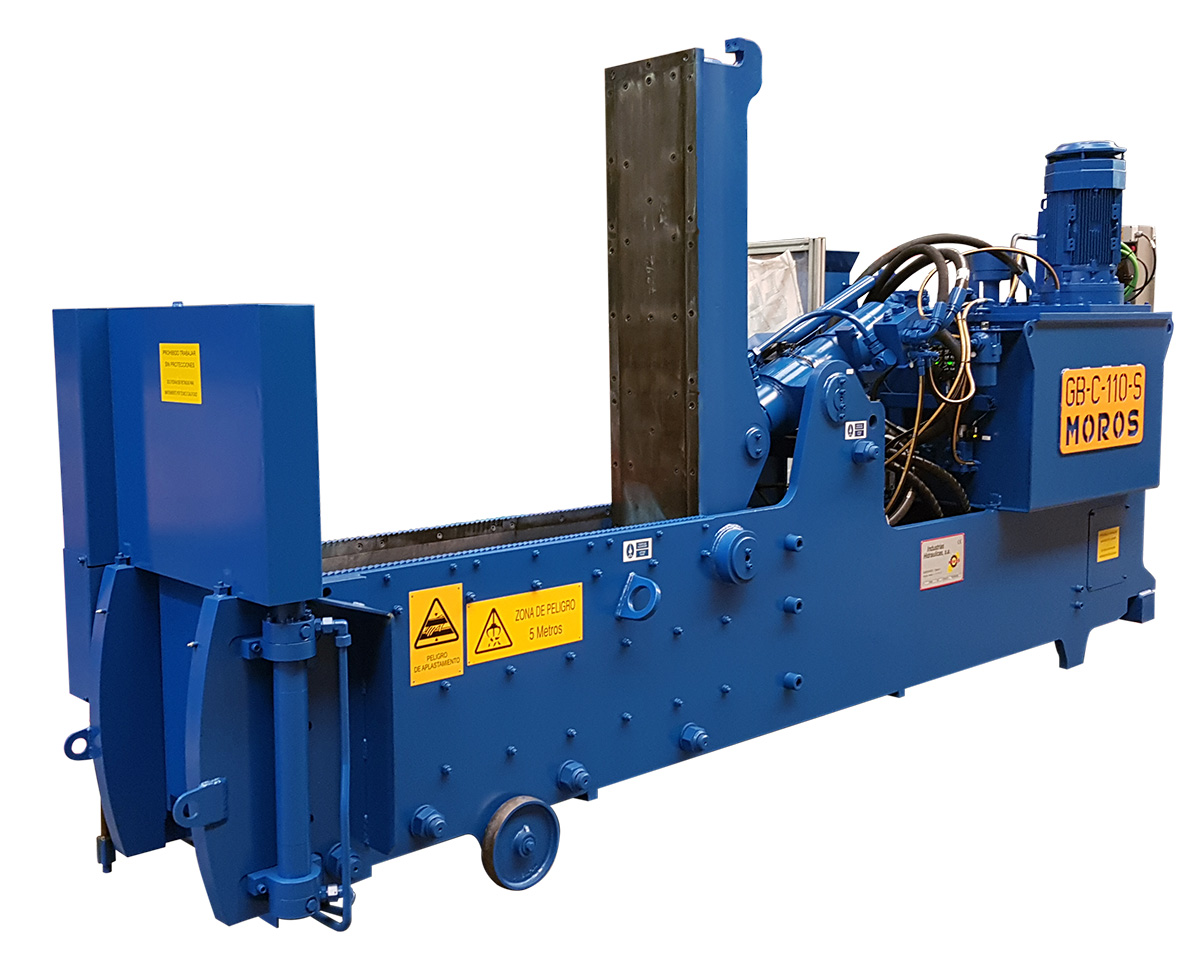

GB-C and GC-E two compression balers

A baler for every need

Availability of several models, both manual or automatic, to adapt to:

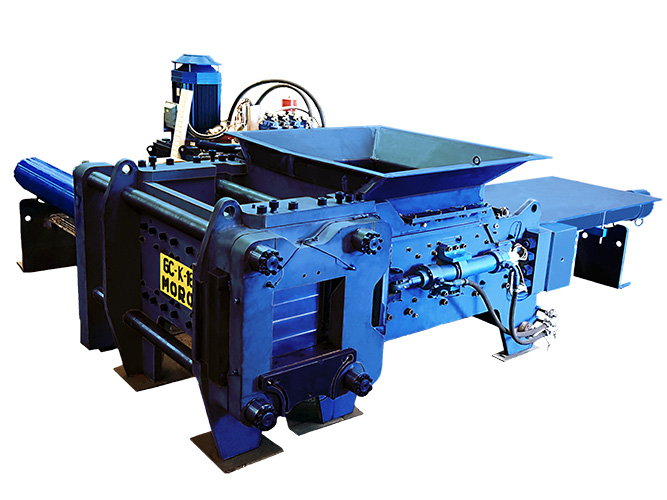

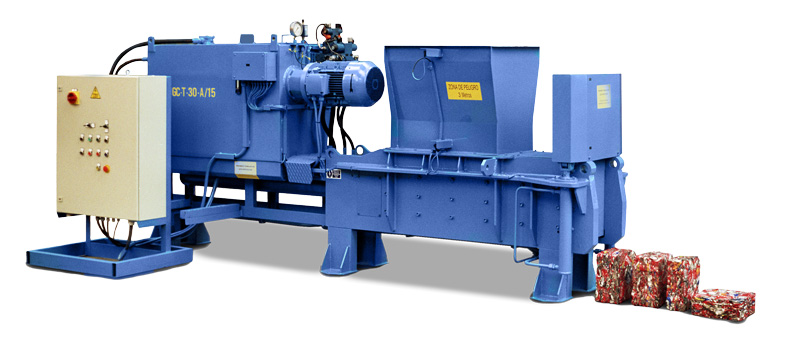

GC-T one compression baler

Excellence in one compression

Balers to process cans and other lightweight scrap that do not require high compacting force.

SPECIAL APPLICATIONS

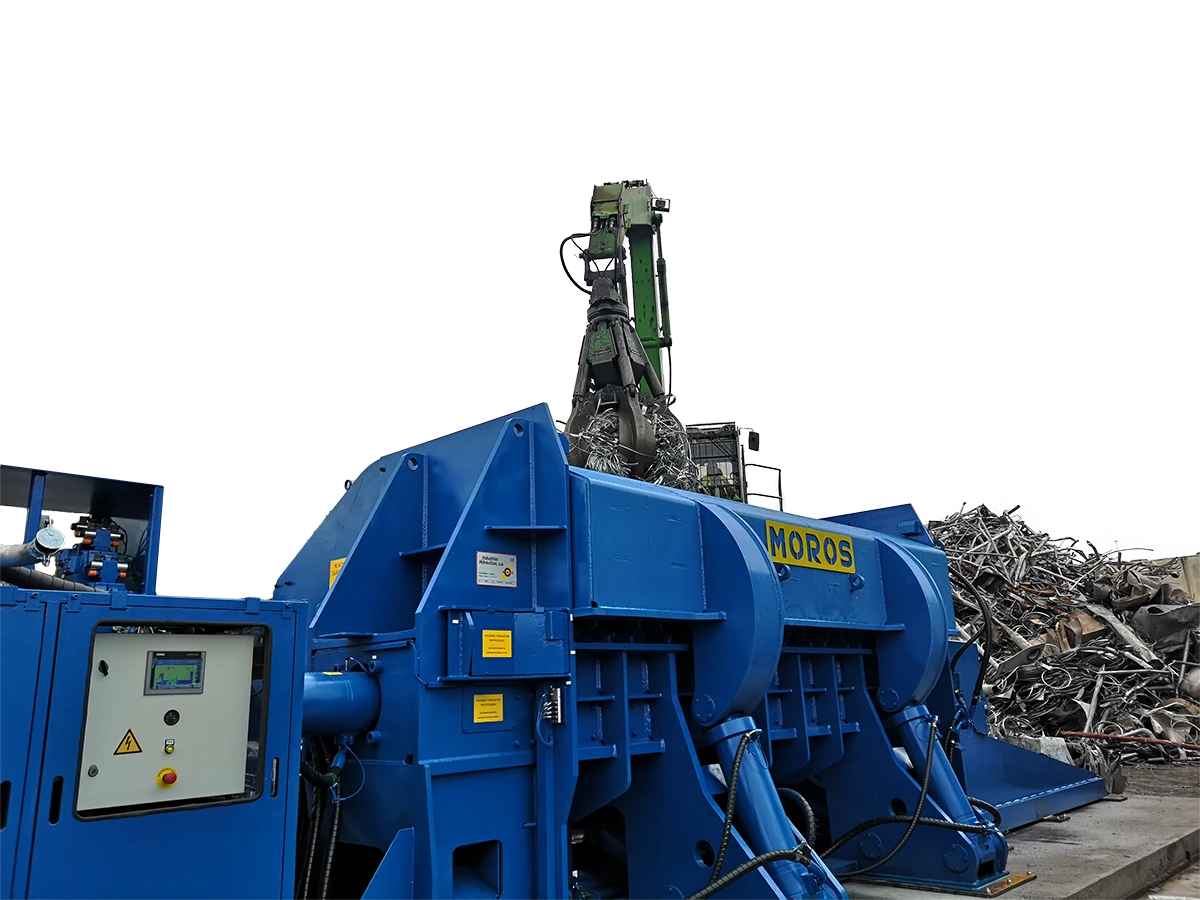

GC-G

3 compression baler with wide lid in first compression to cut exceed material.

GC-L

GC-L

Large load volume

This range of balers produce 1000 x 600 mm bales, and in the reinforced version with spacious box, they can even bale large-sized vans as well as scrap.

These machines derive from mobile balers for cars, which have been adapted, with electric motor and support frame, to work in stationary mode.

GC-M-B